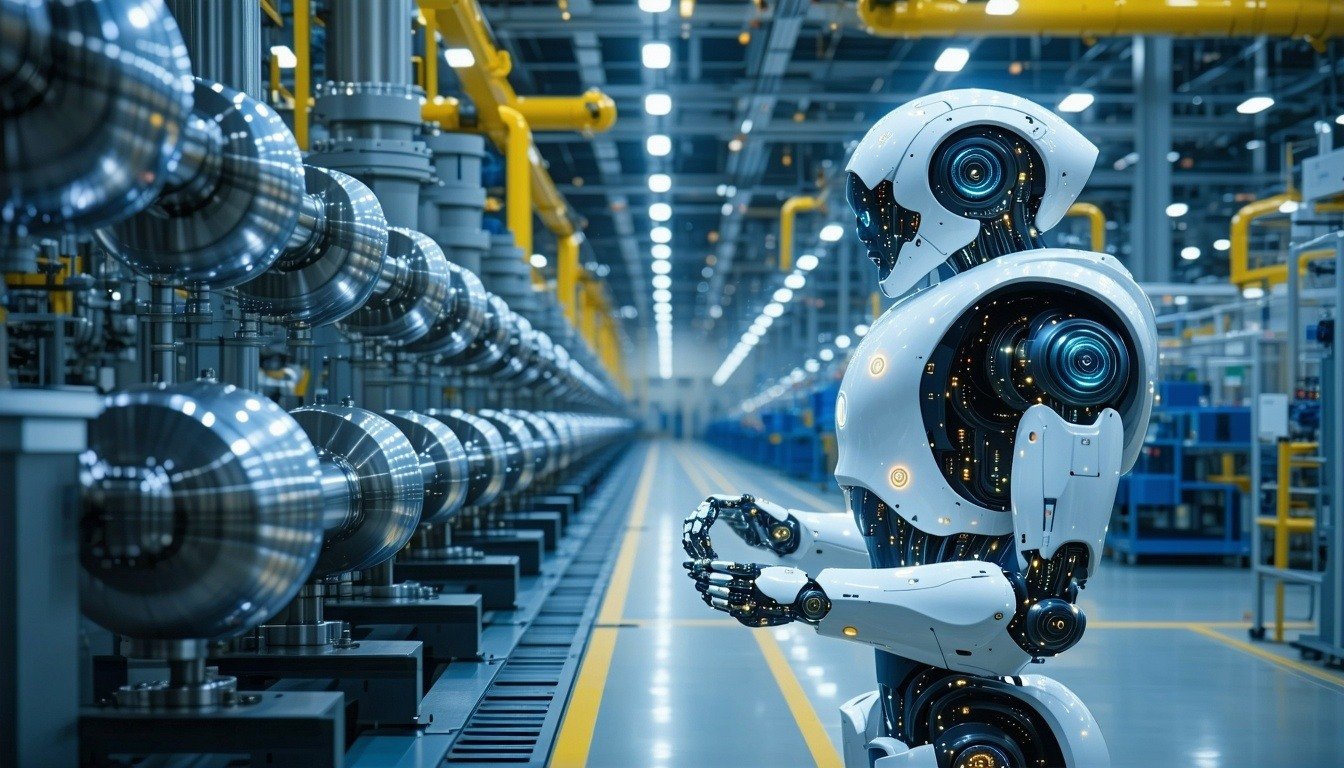

Robotics has become a staple of the manufacturing sector, essential for maximizing productivity, ensuring quality, and reducing labor costs. As valuable as robotics are, many solutions fall short of the time-to-impact metric that manufacturers seek. Enter Artificial Intelligence (AI)-based, closed-loop automation.

Closed-loop, AI software can be thought of as the facilitator of robotics evolution. It ensures that robots adapt to their environment as conditions fluctuate. Without it, industrial robots will be stuck in the past, unable to achieve true digital transformation.

What Is Closed-Loop, AI Automation?

Closed-loop automation is AI-driven robotics that learns and adapts from interactions. It improves task performance, reduces errors, and enables automation in unstructured environments, making previously cost-inefficient tasks more viable for production plants.

When closed-loop AI is applied to robotics, it involves four key phases:

- 1.) Observe: Using sensors, robots gather environmental data to improve situational awareness.

- 2.) Learn: Robots learn tasks through simple natural language instructions or demonstration-based training, enabling them to adapt to the environment.

- 3.) Reason: AI-based logic helps robots make decisions and adapt to events in real time.

- Act: Robots execute tasks by precisely controlling their movements to complete actions.

Overcoming Traditional Robotics Limitations

Training robots for production tasks like line quality inspections and parts sequencing is a complex and challenging process. Traditional methods have struggled to meet the demands of manufacturing due to variable parts, complex assignments, and the need for advanced coding skills. Robotics process automation also typically requires large investments, which are often hard to secure. The main technical shortcoming associated with traditional robotics is their reliance on pre-set predictions and logic, limiting their intelligence and value.

AI in robotics can overcome these limitations, especially when paired with a closed-loop automation framework. Unlike Foundation Models (FMs), which rely on large, generalist datasets, closed-loop AI systems use domain-specific models that are better equipped for robotics applications. By incorporating edge AI computing, these systems lower processing costs, reduce latencies, and improve efficiency. This shift makes AI-driven robotics more adaptable, cost-effective, and capable of handling the complexities of modern manufacturing.

Applying Closed-Loop, AI Automation to Robotics

For robotics solutions to achieve true autonomy, they must be capable of constantly ingesting new data and adjusting accordingly. This is where AI-driven robotics in a closed-loop system is so valuable, as it is designed to thrive in dynamic work environments.

Imagine that you manufacture multiple variations of a single product. This would mean that you will have potentially thousands of different final quality checks across unique Stock-Keeping Units (SKUs). Such a scenario would be extremely time-consuming and laborious for employees. AI-based, closed-loop automation addresses this challenge by performing inspections throughout the assembly line and continuously observing, learning, and reasoning.

As an example of AI in robotics, consider Palladyne AI. The Salt Lake City-based company offers industrial robot-grade software that enables robots to perform quality checks for equipment manufacturers, with AI scanning multiple SKUs in a single line. The edge-based system identifies product models and captures images needed for the final quality check process. Closed-loop automation software like Palladyne IQ not only reduces human error and eliminates downtime, but gives engineers and frontline workers more time back in their day to prioritize other critical tasks.

For a deeper discussion on how AI is changing the way robotics is used and ABI Research’s expectations for user adoption, download the whitepaper: Speeding Robotics Automation with AI.