As we approach the 10th anniversary of the Deepwater Horizon explosion, ABI Research is assessing to what extent Internet of Things (IoT) technologies have been a deterrent of massive environmental and man-made Oil and Gas– (O&G) related disasters. The insight into the reality of O&G-indicated expenditure on IoT analytics and predictive software suggests that the industry is still far from sustainable oil transport and drilling. This article reviews the 10-year synergy between IoT and O&G and provides a future outlook on the next generation of IoT tech.

The Current Energy Tech Paradigm

Since the expansion of IoT technology and sensors and the use of data analytics, O&G has been one of the first verticals to begin the IoT digital transformation. The energy industry is representative of industries with aging equipment and legacy infrastructure constructed decades ago, with some areas of modernizations and nonregular updates. This legacy infrastructure automatically creates a fundamental obstacle to its design by using materials and technologies that were available for integration and compatibility relevant to the time of the construction of the plan or the wells. Like any living organism, the oil wells are expected to fail at some point due to equipment deterioration. Accidents are inevitable in any industry; individually, O&G companies are highly scrutinized over such disasters and therefore have one of the most robust audits. However, taking into consideration modernized technologies, advanced IoT seasons, intelligent processing at the edge—it become apparent, that integration of modern monitoring or preventive technologies is not an easy, cheap or sometimes possible task to the current apparatus. As previously mentioned, errors happen, and so does equipment failure, but unlike in other industries, O&G accidents are influencing living, manufacturing, and natural ecosystems globally.

From an IoT perspective, the O&G industry’s approach to maintenance is slowly moving from reactive to preventive by leveraging a proactive approach to predictive analytics. Unpredictable oil prices and geopolitical conditions are causing greater adoption of monitoring and maintenance technologies. The priority is clear: cut operating costs and optimize maintenance to reduce expenses. The preventive maintenance approach that requires inspection and maintenance at regular intervals is considered practical. However, the ultimate question is whether the multibillion contract with IoT service providers can exist in the real world. So far, the technology has failed to “prevent” complete machinery breakdowns.

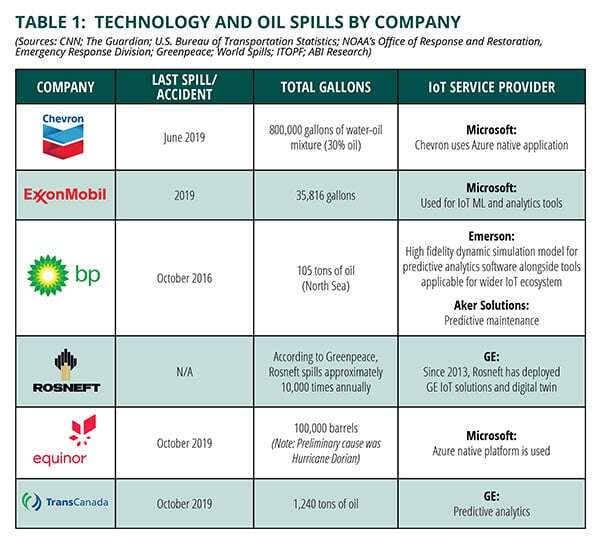

Reality Check: The last oil spillage occurred on December 4, 2019, near San Francisco Bay in California with more than 200 gallons of fuel spreading through the lagoon. This event follows Chevron’s spill in June 2019 where 800,000 gallons of the oil-water mixture was spilled (30% of it was oil). Finally, according to the U.S. Bureau of Transportation Statistics, the year 2019 saw approximately 2,000 oil spill incidents. The reality is that since the Deepwater Horizon event, oil spill statistics indicate more than 610,488 tons of fuel have been spilled globally.

Operational Business Intelligence in O&G: Industrial Challenges

Considering the current industry dynamic and rapid IoT transformation for top O&G players, it is relevant to look at the business intelligence and analytics challenges. Why do they seem to only promise Returns on Investment (ROIs)?

Challenge 1. Big Data: The O&G industry is a continuous processing industry consistently producing commodities—meaning that it generates a vast amount of information every second. The industry is transitioning its flow of information from sensors, detecting such elements as temperature, pressure, fluid viscosity, the presence of foreign substances, and seismic activity. First and foremost, technological advancement in the big data domain is still in its incumbent stage—and specifically in the IoT domain. Second, giant oil suppliers seem to turn to big data solutions to look for “all the answers” while big data solutions at the current historical conjunction are still predominantly concerned with ingestion and storage capabilities over advanced analytics.

Challenge 2. Advanced Analytics and Artificial Intelligence: Integration of Artificial Intelligence (AI) and advanced-analytics automating functions is still far in a horizon—this is just the reality. It is possible to apply AI-generated actionable insight into batch (non–real time) data processing and produce valuable analytics. However, a closer look at the predictive maintenance and O&G type of infrastructure reveals that real-time AI application does not exist yet. While top oil players market themselves as pro-tech, with predictive analytics being the key to their investment, consulting firms and the hiring of a few experts is not making the technology work and subsequently not making a difference in preventive measures.

Challenge 3. Capturing and Localizing Leaks: The current technologies for leak detection and prediction of such incidents is based on the known locations of reporting sensor nodes. The scalability of the pipeline leakage detection sensor network can constitute an utterly separate challenge since it would include a full-scale coverage of the pipeline network, which is enormous. In this case, the leak detection mechanism tool sets intertwined with various localization techniques can address the concerns, if only they were not transmitted as batches of data. In this regard, localization techniques with satisfactory performance will be a welcome addition to the leak detection mechanism toolbox. Conventional sensor-based monitoring is not able to deal with these types of problems, while a streaming analytics engine can.

Challenge 4. Expectations and Capabilities Gap: Following the previously acknowledged challenges, ABI Research has concluded that one of the biggest downfalls and challenges of IoT analytics in O&G is the c-suite expectations and capabilities gap. There is a trend for managers to not see a quick ROI from IoT analytics or to not see any business value at all since they are looking for a “saving on reduced downtime” rather than an investment in precaution. Across the IoT industry there is a misconception of what analytics entails and how the c-suite would use the insights coming from connected devices. The reality of the market is that the automating processes of data readability, filtering, cleansing, enrichment, and so on is at the early stages. There is arguably a need for technology advancement and democratization since teaching an operator complex data science is not always possible and is unrealistic. Hence, the expansion of IoT analytics efficiency is available, while the capabilities to accomplish it is not.

Challenge 5. Auditing of Data-Driven Decision Making: Concerns grow over the auditing of the already-made decisions, which are the subject of Machine Learning (ML) and sophisticated algorithms. Building AI and ML algorithms is a complex process, and currently there is no auditing trail for decision making or scrutiny over the parameters that are driving ML tool sets. There is a need for auditing and due-diligence procedures to construct and understand the AI decision outcome, as this is currently lacking. The debate centers on whether the oil company or operating or transporting company is responsible for leakage and whether this also extends toward technology providers. Table 1 shows that major oil companies are using technology vendors for predictive analytics and other IoT solutions. However, when it comes to accidents, those vendors are not included in the scrutiny and the conversation about responsibility.

Ten Years Ahead: The Next Generation of Technologies

Looking 10 years ahead, the O&G industry can expect a long patch of digital transformation, tightening standards, and embracement of corporate social and environmental responsibility. The reality is that predictive maintenance is not entirely addressing preventable accidents and mistakes. Therefore, it needs a new perspective and evaluation of future capital expenditure to address aging facilities, digital modernization, and the analytics for oil wells. ABI Research believes that the future uptake in the industry will be IoT streaming analytics technologies. The modernization and rapid upgrade in cloud-based, real-time-analytics IoT technologies alongside the rise of operational technology such as digital twin is raising the possibility of improving preventive maintenance and increasing reliability of monitoring tools and techniques.

The following types of solutions, therefore, have the potential for enabling better capabilities to predictive and prescriptive analytics before equipment failure:

- Real-time ingestion and analytics from the sensor alongside cross-reference and comparison with newly generated technical data

- Comprehensive-time windowing libraries

- Ingestion, processing, and storage of real-time and historical sensor data at the edge, in the fog, and in the cloud

- Pattern recognition of normal and errant behavior across various types of equipment in the real-time for provision of warning systems.

The third generation of streaming technologies from the IoT domain will allow remote monitoring to reduce the risk of human mistake (and loss of lives) and provide the ability to analyze continuous streams of events producing analytics of high speed, real-time sensor data streams that can handle over 100 million data points per second.

For additional information on IoT Streaming Analytics technologies, subscribe to ABI Research's M2M, IoT & IoE research service, which includes data, trend, and forecast reports, and uncovers emerging trends and predictions for market growth across connections (fixed, satellite, cellular, short-range wireless), connection management, IoT platforms, data and analytics, security, and professional services.