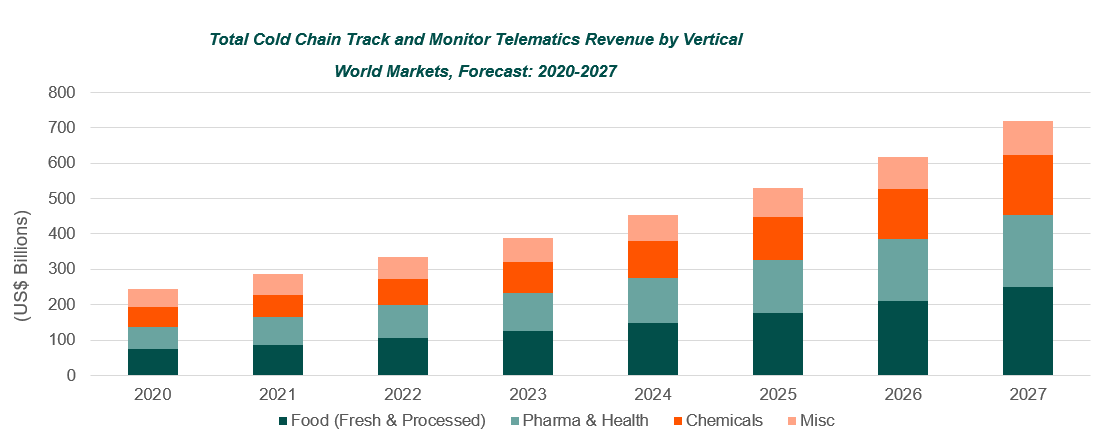

In 2021, the global cold chain track and monitor telematics technologies market size was US$286 billion, according to ABI Research. By 2027, the cold chain telematics industry will be valued at over US$700 billion and growing at a Compound Annual Growth Rate (CAGR) of 16.6%. As 20% of perishable goods are wasted during shipping, cold chain logistics managers are turning to technological solutions to monitor shipped goods.

Why Telematics is A Great Technology for Cold Chain

Supply chain challenges have caused a higher frequency of delays that put a strain on refrigerated goods. There are also regulatory compliances introduced by governments to tackle environmental issues and food/pharmaceutical safety concerns, introducing dilemmas for organizations to address. Fleet telematics technologies enable supply chain operators to track all the data associated with products being shipped.

Meanwhile, new drug products often require cool temperatures throughout the shipment process. It comes as no surprise that 92% of pharmaceutical leaders are planning to invest more in cold chain technologies that provide supply chain visibility, according to a study from Zebra.

The practicality of cold chain visibility is that organizations can see at what stage of the process products are getting damaged. So, when the temperature of products starts to rise, management will know in real time and can make proactive adjustments.

Biggest Use Cases for Cold Chain Technologies

Making up 30% of market revenue, the food industry is the greatest use case for cold chain track and monitor telematics technologies. As demand for perishable food products like canned goods, seafood, fruits, and vegetables grow in underdeveloped markets like Latin America and Asia-Pacific, so does the demand for telematics vendors. Facts and Factors forecast that the global food cold chain market size will grow at a CAGR of 7.8% between 2021 and 2026, amounting to US$366.8 billion.

Pharmaceuticals is another industry that heavily invests in cold chain fleet telematics technologies as 80% of European Union (EU)-based pharmaceuticals need temperature-controlled transportation and the U.S. Food and Drug Administration (FDA) continues to introduce more compliances. The best example of fleet telematics in the pharmaceutical industry is the need for cold chain refrigerators for vaccine storage.

The third biggest use case for telematics technologies comes from the temperature control needs of chemicals. For example, the chemicals used during the manufacturing process of semiconductors require accurate temperature regulation throughout transportation. As you can see, telematics is crucial for improving fleet management operational efficiency.

IoT Sensors in Cold Chain Logistics

Usually placed on a pallet, individual item, container, or vehicle, an Internet of Things (IoT) sensor is a type of technology that tracks the location of shipments in real time. In addition to geotracking, IoT sensors can monitor environmental conditions like temperature, humidity, and Carbon Dioxide (CO2) levels. Through cloud transmission to a software platform, IoT sensors share key conditional data with workers or managers and alert them of deviations. That way, companies can take countermeasures immediately.

Figure 1: Roambee BeeSense

Data Loggers Record the Temperature Level of Shipped Goods

Possessing large internal storage capacity, data loggers are often used to store temperature information sent from sensors. This kind of cold chain technology can pinpoint the exact time when temperature levels depart from a specified range. Loggers that are connected via a Universal Serial Bus (USB) can convert the data into Portable Document Format (PDF) files containing graphs and charts. Besides a USB connection, data loggers also use Near-Field Communication (NFC) and QR codes to transmit data to a computer or mobile application for review.

Figure 2: Emerson GO TH Logger

Fleet Telematics Visibility Platforms

The data processed by IoT sensors and data loggers are of no use without being able to visualize them. Visibility platforms, such as Controlant’s Cold Chain as-a-Service platform, allow users to analyze insights and analytics stemming from tracking devices—and turn the data stemming from cold chain technologies into something meaningful. Dashboards, display trends, and graphs all promote greater cold chain visibility.

The benefits of a visibility platform include:

- Real-time visibility

- Scalability

- Quality and safety compliance

- Cost reduction

- Risk mitigation

- Sustainability

Blockchain Technology for Secure Transparency Throughout the Supply Chain

Cold chain logistics are often complex, so blockchain is a great technology that provides a straightforward, yet secure way for all parties to complete purchase orders and track assets. For example, a temperature sensor may distribute data throughout a blockchain network so that each party knows that they’re looking at a tamper-proof set of data. When blockchain is implemented, all supply chain partners are provided with a single source of record keeping.

Smart contracts automate final agreements as soon as predetermined conditions are met, i.e., an order is placed as soon as digital payment is sent. And only verified users can gain access to the document. Smart contracts eliminate the need for an intermediary, so organizations can save time and money while being confident about data integrity.

Cold Chain Technologies Make Stakeholders Happy

All too often, perishable products are deemed damaged, resulting in a monetary loss that could easily be prevented with cold chain technologies that provide real-time tracking of temperature levels. As e-commerce shopping is growing at unprecedented levels , the risk of perishable products getting damaged during the supply chain only increases.

For companies shipping food, pharmaceuticals, or chemicals, the time has come to get serious about telematics. Companies that hesitate to adopt devices and software promoting cold chain visibility are destined to become industry laggards. While the competition reduces the frequency of damaged goods as a result of temperature fluctuations, the laggards will upset business partners and end customers.

To learn more about how telematics technologies can boost the food and pharma cold chains, download ABI Research’s Evolving Technology Solutions for Cold Chain Logistics report in either PDF or PowerPoint form.

Related Content:

8 Best Practices for Improving Fleet Management [blog]

6 of the Most Essential Fleet Management KPIs That Will Boost Your Bottom Line [blog]

Beefing Up Fleet Telematics Hardware Security [blog]

Is Your Fleet Management Plan Factoring in These Compelling Strategies? [Research Highlight]