Although the world is gradually crawling closer to a full escape from the clasp of COVID-19, some of the effects of the pandemic are still being felt in supply chain logistics. As a result of lingering issues, such as labor shortages and port holdups, suppliers are still struggling to meet satisfactory delivery windows.

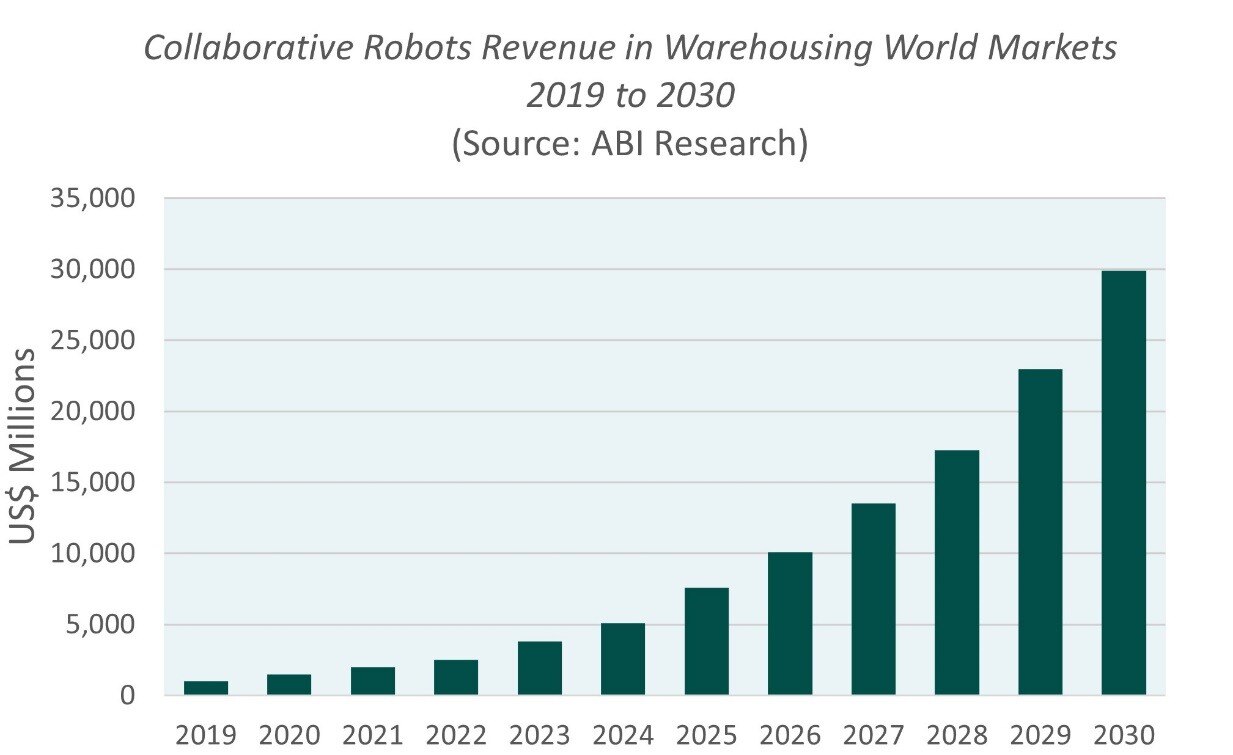

Companies are shifting their approach to supply chain efficiency. Some companies have moved away from the Just in Time (JIT) delivery model while investing in technologies like robotics, automation, demand planning, Warehouse Execution Systems (WES), and reshoring. But edge computing is one type of technology that is especially useful during a time when central data centers are overburdened with traffic.

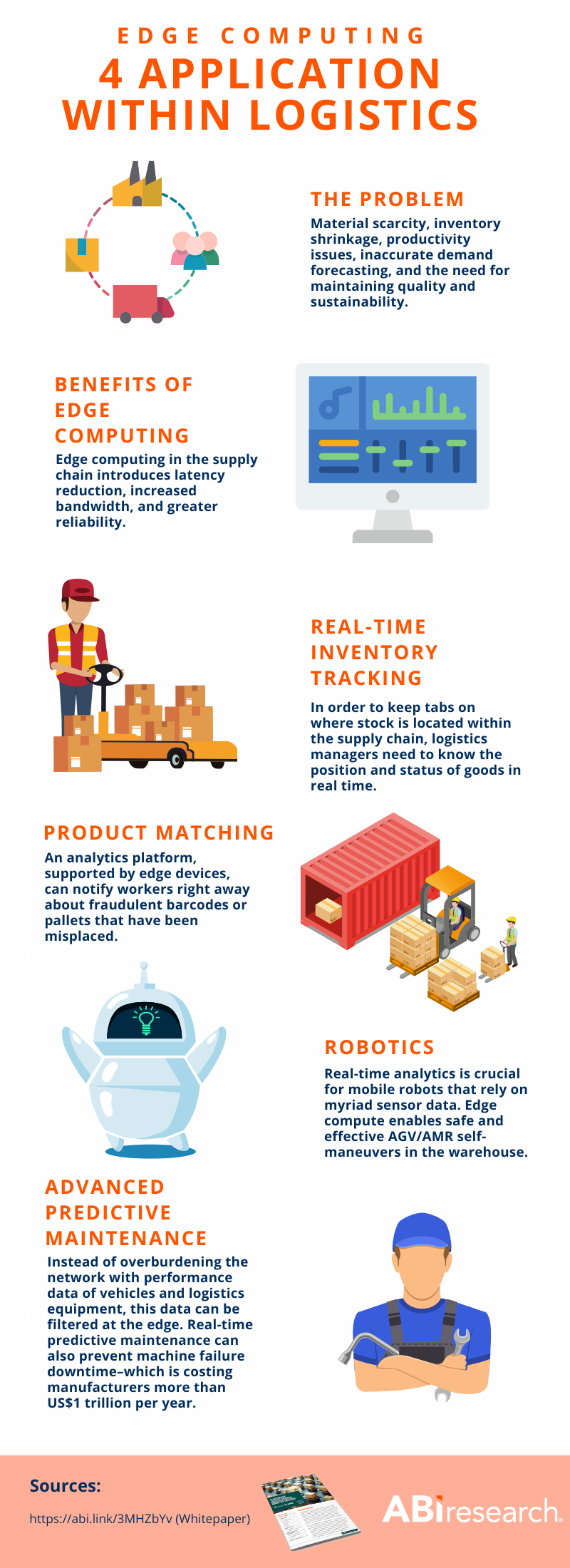

Infographic: How the Edge Benefits the Supply Chain and Logistics

The infographic below provides a brief background on how edge computing can be applied to supply chain and logistical operations. As you'll see, edge compute provides reduced latency, wider bandwidth, greater reliability, real-time inventory tracking, product matching, robotics support, and advanced predictive maintenance for warehouse equipment.

How Does Edge Computing Make the Supply Chain More Efficient?

Central servers often suffer from information overload, resulting in costly processing delays. Edge computing, on the other hand, is a technology that enables data processing at the local level. So, instead of having all the data from a warehouse’s Internet of Things (IoT) devices be sent to and processed at a remote central data center, edge computing accomplishes the same goal on a smaller server close to the source.

Edge computing helps with supply chain efficiency because it frees up resources, lessens the reliance on human management, and vastly increases the latency for time-sensitive processes. As companies invest more in IoT devices and demand faster results for warehousing and transportation processes, edge computing is positioned as a lucrative option for companies looking for logistics management solutions.

Real-time inventory tracking, a potential US$18.8 billion market growing at a Compound Annual Growth Rate (CAGR) of 28% until 2028, is a much-needed technology for supply chain optimization. With edge computing, a shipment’s location can be accessed at any moment. For logistics managers looking to improve their supply chain, tracking the status of a shipment involves large sums of data with minimal interference, where edge computing specializes.

Edge computing can safeguard against fraudulent activity and human error in the form of product matching. Warehouse workers can be alerted instantly as soon as a scanner detects something is wrong.

Mobile robots, like other devices that collect and transfer large quantities of data, are limited by traditional central servers. But when a robot leverages edge computing, real-time analytics becomes possible and allows it to navigate more logically.

Downtime is a major problem in manufacturing. The International Society of Automation reports that the biggest manufacturers in the world lose US$1 trillion per year combined because of machine failure. However, machine failure can be mitigated with real-time performance tracking of equipment that sends an alert when a part is failing. As an example, if a forklift in a warehouse was underperforming, a sensor would send the conditional data to a local edge container—prompting management to order a new part or schedule a repair before a major problem materializes. Predictive maintenance, as it's called, requires numerous sensors to transfer data, so it would be too burdensome on a central server.

Real-World Example

As the world’s leading manufacturer of home appliances, Whirlpool’s logistics management requires a substantial number of mobile solutions throughout its distribution centers. Management knew that in the interest of supply chain optimization, they would need a solution that tackles the following problems:

- Device misplacement

- Battery life

- Service updates

- Performance tracking

Whirlpool decided to partner with Industrial Service Technology (IST), which uses the technologies provided by the mobile computing company, Zebra. These technologies include Zebra XT15 mobile computers, VH-10 vehicle-mounted computers, and Zebra’s Operational Visibility Service (OVS). After implementing these edge technologies, Whirlpool had the newfound ability to identify an arising problem, analyze it, and take proactive action in real time.

All the data, analytics, and visibility of Whirlpool’s assets were accessible with Zebra’s OVS. Some of the asset information Whirlpool monitored included battery performance, device utilization, location, configuration, inventory, etc.

With the deployment of Zebra’s logistics management solutions, IST and Whirlpool improved supply chain efficiency tremendously. In just a little over 2 months, it recovered 63% Return on Investment (ROI).

Meeting Consumer Demands

Consumers are fully accustomed to online shopping and, as a result, their expectations are only increasing. The Retail Industry Leaders Association reports that 90% of customers say a 2 to 3-day delivery window is a basic expectation at this point. What’s more, nearly a third of e-commerce shoppers expect same-day delivery.

For supply chain leaders and vendors looking to make their logistics management more efficient during the global supply chain crisis and perpetual labor shortages, edge computing should be top-of-mind as an end to end supply chain solution. Edge computing presents an opportunity to track shipments and assets in real time, empowering managers to be proactive, instead of reactive. At the same time, opting to have data distributed through a network, as opposed to one central server, enables latency and server optimization.

To learn more about technologies revolutionizing supply chain logistics, download the free whitepaper Transforming Logistics Through Connected Solutions sponsored by Zebra Technologies.