Few would argue that the automotive industry can be complex. Everything from model design to after-sales services requires a large sum of resources and pinpoint accuracy. To ease the pain, Augmented Reality (AR) can enhance nearly every facet of car manufacturing because it allows assembly line workers to go hands-free. Besides, most carmakers already have existing platforms that can take advantage of AR.

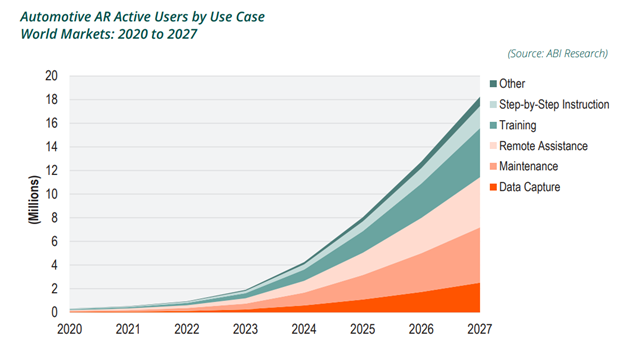

As augmented reality has shifted from the ”education phase” in the manufacturing space to a more mature market, ABI Research expects automotive smart glasses shipments to approach the 2 million mark by 2027. Furthermore, a recent survey from GridRaster, a provider of cloud-based Extended Reality (XR) platforms, found that two out of three manufacturers are exploring ways to incorporate the metaverse into their operations. While the metaverse may be more of a long-term solution for car manufacturers, it goes to show that virtual environments are here to stay. Indeed, there are plenty of other ways augmented reality is already making an impact in the automotive industry.

Types of Augmented Reality for Car Manufacturers

Car manufacturers have a few options when it comes to immersive augmented reality technologies. The three main device categories are assisted reality smart glasses, mixed reality devices, and mobile devices.

- Assisted Reality Smart Glasses: These devices are typically monocular (single display) Head-Mounted Displays (HMDs). The focus for assisted reality devices is on quick access to information and optimal user vision. Two-Dimensional (2D) content display and onboard cameras (for data capture) add further value. Two examples of assisted reality devices are RealWare Navigator 500 and Vuzix M400.

- Mixed Reality (MR) Devices: These types of AR devices are Binocular (dual display) HMDs that can provide Three-Dimensional (3D) spatial tracking. Microsoft’s HoloLens 2 is the star product in the MR domain. Because AR devices provide greater environmental awareness and immersion than assisted reality, they are also more expensive and complex to implement and maintain than assisted reality devices, on average. But the good news is there are low-code and no-code platforms that automotive players can leverage for better ease of use.

- Mobile AR Devices: Although not nearly as robust as assisted reality and MR devices, mobile AR devices do provide convenience at a low-cost entry point. For that reason, AR-enabled mobile devices are an attractive option for resource-lacking automakers. Unfortunately, mobile devices lack hands-free capabilities and 3D experiences that are game-changers in the AR space. Apple’s ARKit and Google’s ARCore are examples of mobile AR devices.

Hands-Free Assembly Lines and Superior Training

Because augmented reality and mixed reality smart glasses provide hands-free access to data, car manufacturing workers are equipped with the information they need without having to take any extra steps. Not only does this bolster workplace safety, but it also creates immersive 3D visualizations that result in a greater likelihood of content recall. Of course, the latter is especially useful for training purposes.

To back up this claim, a recent University of Maryland study found that people had an 8.8% improvement in recall accuracy using a virtual learning environment. And research published by The International Journal of Advanced Manufacturing Technology showed that manufacturing assembly line workers trained by Virtual Reality (VR) make fewer mistakes and are more efficient with their time than their counterparts who use traditional training methods.

Smart glasses with AR and MR capabilities enable car manufacturers to assemble vehicles with step-by-step instructions and track Key Performance Indicators (KPIs). Imagine a car manufacturing plant where individual employees can complete their tasks and receive operational updates without the need for face-to-face communication. It goes without saying that these capabilities pave the way for a much higher level of operational efficiency while reducing downtime.

Augmented reality can also be used in vehicle manufacturing for remote assistance, where a technician can diagnose a problem and provide guidance virtually. Remote assistance, as reported in our trends paper, is a huge cost saver because it eliminates the need for an expert to travel to the manufacturing facility. On a related note, AR visually-guided assistance to frontline workers also enhances employee skills, which inevitably reduces error rates.

Chart 1: Augmented Reality Active Users by Car Manufacturing Use Case

Artificial Intelligence Will be Key for Augmented Reality in Car Manufacturing

We already see Artificial Intelligence (AI) being deployed in virtually every business category, so it’s not surprising that AI will be critical in automotive AR use cases as well. In addition to data processing and analytics, AI can provide automation and prediction with AR content. For example, an expert technician may provide remote assistance to an end customer, then that session can be recorded and uploaded to a training video database. From there, AI can recommend the most suitable training modules for car manufacturers, negating the reliance on a live session.

Object Detection and Seamless Workflows

Machine vision, which is a feature of AI, can be used for enhanced car production workflows because this technology can tag physical objects that a worker sees when wearing an AR device. So, an assembly worker may see a vehicle part or component in the physical environment, and there will be digital content locked to it—providing instructions, best practices, etc. Another way to look at it is to think of an AR machine vision model as an automated workflow. Instead of an assembly line worker chasing down a colleague or informational resources about a manufacturing process, an AI-enabled platform will utilize existing content to deliver Just In Time (JIT) guidance—saving considerable time and resources.

Actions to Take When Adopting Augmented Reality for Vehicle Production

Before adopting augmented reality devices for car manufacturing, it’s important to identify the specific operational areas that could benefit the greatest from deployment. To decide how AR implementation ought to be carried out, existing platform managers and departments, such as Information Technology (IT), will need to come together and brainstorm. Such collaboration will help see where technological symbiosis lies and which hardware investments are required.

While most AR solutions are designed to address either upstream or downstream applications, all-in-one solutions like TeamViewer’s Frontline platform can provide even more value as it provides greater flexibility without sacrificing the quality of features.

These findings come from ABI Research’s Automotive Sector Complexities And The Role Of Augmented Reality whitepaper sponsored by TeamViewer. Get it today.