Modern supply chains are extremely complex, involving various stakeholders, regions, transport systems, and even standards. Adding to this complexity is the fact that various software systems used for supply chain management generate data in their own separate silos. It’s tough to draw definitive conclusions and improve supply chain operations when data are disorganized. Therefore, acquiring a unified inflection point that captures all these data in a single location is essential to keep operations running smoothly. Enter supply chain control towers, which give logistics operators full visibility into various systems, processes, assets, etc. in one platform.

If you’re thinking about adopting a supply chain control tower or you’re a software provider offering these solutions, this blog post explains everything you need to know about the increasingly popular technology.

What Are Supply Chain Control Towers?

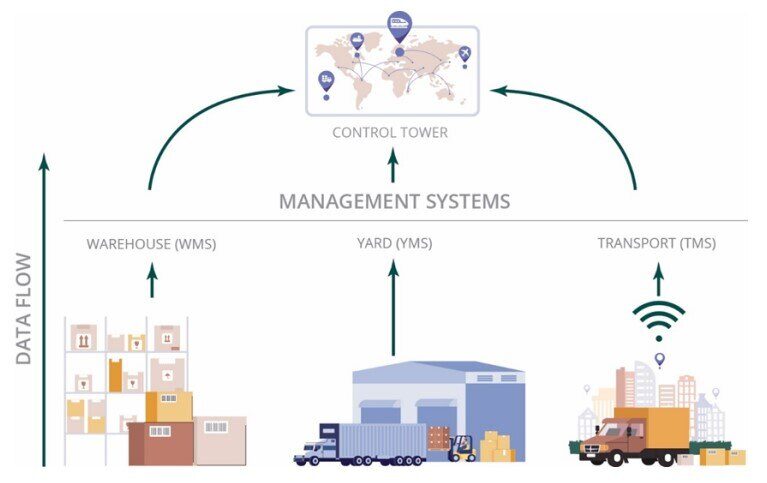

A supply chain control tower can be defined as a central hub that provides visibility into all aspects of the supply chain. Control towers connect previously siloed and disparate data, key business metrics, management systems, and real-time event updates. By having one central source of visibility into processes, people, data, organizations, and technologies, supply chain management and collaboration is made much simpler.

While they can vary in specific features, below identifies the most prominent control tower capabilities:

- Basic Visibility and Data Aggregation: Track the status of assets and transport, sourcing data from operational systems.

- Collaboration and Analytics: Leverage various supply chain data generated through various systems, which can be leveraged for a more thorough analysis of operations. Connecting all these data enables supply chain operators to improve collaboration with partners and drivers.

- Scenario Analysis and Decision Support: Some control towers on the market provide more robust End-to-End (E2E) solutions, such as Artificial Intelligence (AI)/Machine Learning (ML)-based recommendations. Moreover, the control tower allows users to simulate different scenarios (e.g., out of stock allocations, etc.) using a digital twin of the supply chain.

- Autonomous Control and Execution: The most advanced supply chain control towers available today maximize the use of AI and ML for prescriptive and predictive analytics. AI-powered control towers go beyond just offering visibility, control, and recommendations; they can remedy bottlenecks and optimize supply networks without the need for any human intervention.

Figure 1: Data Flow from Tracking of Assets to a Supply Chain Control Tower

(Source: ABI Research)

Read more:

A 13-Point Checklist for Selling Supply Chain Control Towers

The Rise of “Cognitive” Supply Chain Control Towers.

Supply Chain Control Towers Competitive Ranking

Why Are Supply Chain Control Towers Important?

The key benefit of a supply chain control tower is that it provides companies with a single source of truth. As supply chains continue to become more globalized and digitalized, it’s easy for key stakeholders to be left out of the loop on delivery updates, demand forecasts, etc.

At the same time, companies have introduced more software solutions such as Warehouse Management Systems (WMSs), Yard Management Systems (YMSs), and Enterprise Resource Planning (ERP) solutions. These software solutions target different aspects of the supply chain and come from various technology vendors, which can cause interoperability issues and data silos.

These challenges can be overcome by adopting a control tower. It is an all-inclusive dashboard that combines real-time supply chain visibility and updates from each platform. From there, operators can be sure they have all the necessary information to make more informed decisions. Ultimately, deploying a control tower provides the benefits of enhanced supply chain performance, controlled costs, increased agility/resiliency, and improved customer service.

Table 1: Evolution of Supply Chain Control Tower Capabilities

| When? |

Type of Deployment |

Primary Function |

| Past |

Single deployments |

Focused on transport visibility and enabling stakeholder collaboration. |

| Present |

Multiple, siloed control towers |

Expanding to more areas such as inventory and fulfillment. Users starting to use predictive analytics and network optimization functions for supported decision-making. |

| Future |

One E2E control tower |

Advanced functions such as digital twin, scenario analysis, and automated decision-making. |

(Source: ABI Research)

Market Drivers of Supply Chain Control Tower Adoption

Based on my review of the market, here are the four key reasons behind the increased adoption of supply chain control towers:

- Harmonizing Data and Processes: Central planners are tasked with analyzing the supply chain and identifying key trends. With data originating in various areas of the supply chain and from myriad operational systems, these tasks are challenging. Companies with large supply chain networks are increasingly interested in using control towers to combine all these key data into one dashboard.

- Aligning Supply Chain Areas: If you manage an individual department, distribution center, storage facility, or transport division, then you’re primarily concerned with optimizing your own neck of the woods. Ideally, each of these supply chain areas should be coordinating with one another and have real time visibility into each other’s operations. Adding a control tower provides a “top down” level of control, thereby enabling organizations to optimize stock inventory management, resource allocation, etc.

- A Need to Leverage Supply Chain Data: Most supply chain leaders already understand the immense value that large sums of data possess. However, they struggle to leverage these data due to discrepancies between various data flows. Some of this issue stems from a lack of data management expertise, but outdated systems and the omittance of supported analytics is a huge culprit as well. A supply chain control tower consolidates all these data sources so that companies can more easily make use of predictive analytics.

- Necessity for Optimizing Networks: Supply chains worldwide have had several wakeup calls recently. The COVID-19 pandemic, the Suez Canal blockage, high inflation, worker shortages, inventory surplus, and regional conflicts have exposed logistical flows. It’s now understood among supply chain leaders that mere visibility isn’t enough to circumvent unforeseen hindrances. Therefore, advanced tools such as AI-supported control towers are deemed a must-have to conduct in-depth analyses and organize inbound deliveries.

The YouTube version of this section can be viewed below.

Barriers to Control Tower Adoption

While adopting a supply chain tower sounds like a huge win, there are still some reasons why a company may wish to avoid them. Here are the top supply chain control tower adoption challenges:

- Exposure of Weaknesses: For one thing, control towers generate huge sums of data from each supply chain partner. That means if supply chain bottlenecks can be traced back to a specific manufacturer or Logistics Service Provider’s (LSP) warehouse, it exposes their weaknesses. Of course, these companies would not want to be deemed the “weak link” in a supply chain as it would elevate the risk of being dropped as a retailer’s client.

- Data Quality Concerns: Another concern about control towers is data integrity. Many companies are hesitant to adopt a control tower for their supply chain because they don’t think the solution will be effective if data feeds are not completely cleaned up first. More sophisticated AI-supported control towers are the best option, as they are better at handling imperfect data and can correct data over time.

- Dark Points in the Supply Chain: Some management system solutions are mature and data are easily retrievable for the supply chain control tower. However, more nascent solutions like YMSs are relatively new to the market and data tracking is not always optimal. This lack of data visibility remains an obstacle to full E2E control tower solutions.

- High Costs and Customization Requirements: According to industry interviews ABI Research has conducted, end users still find the costs of network-wide control towers to be a prohibitive factor to adoption. The idea of a “plug-and-play” solution has not come to fruition. Some vendors are offering “pay-as-you-go” pricing models, but they are not the norm. Therefore, the industry must work toward providing more scalable Software-as-a-Service (SaaS) solutions that match the specific requirements of an individual supply chain.

Summary

In summary, supply chain control towers connect an organization’s supply chain to improve visibility, better utilize data, and promote collaboration among key stakeholders. This is a monumental upgrade from the historically disparate sets of data that, for the most part, go unused for optimization. These technology solutions bring supply chain accountability to new heights, which will help pinpoint where operations need further support. In turn, control towers directly correlate with supply chain optimization and superior customer satisfaction.

For more on the current market/competitive landscape, use cases, key functionalities, and strategic guidance on control towers, download ABI Research’s free whitepaper, Supply Chain Control Towers: A Simpler Route to Full Visibility.