What Is IoT Remote Monitoring?

Internet of Things (IoT) remote monitoring provides real-time conditional and usage data about equipment, machines, and infrastructure. IoT sensors are placed on or in assets to make this possible, revealing various metrics. Remote monitoring of IoT assets is essential for organizations to improve efficiency, address problems before they exacerbate, and make informed decisions.

IoT remote monitoring empowers you to identify issues before equipment fails, a machine goes down, or a structure collapses. Remotely managing an asset can be done from anywhere, translating into quick, data-driven decision-making. Through timely maintenance, your organization can maximize the longevity of assets.

Benefits of IoT Remote Monitoring

Some of the main benefits of IoT remote monitoring include the following:

- Reduced Downtime: Detect early signs of equipment/machine deterioration to prevent the asset from being pulled from operations.

- Lower Maintenance Costs: Remotely managing assets allows you to take a proactive approach to equipment/machine maintenance. Real-time data analytics reveal a potential issue early on, allowing you to apply a remedy before it becomes more expensive to fix.

- Sustainability: Hospitality and retail companies can optimize energy consumption levels as IoT sensors relay energy data at an appliance level. Moreover, industrial firms can remotely track the energy consumption of specific equipment to help achieve their sustainability goals.

- Safety: Applications like refrigeration monitoring and gas detection are instrumental to food safety and hazard prevention. Furthermore, remotely monitoring the health of bridges, railways, and other civil structures minimizes the risk of a tragic disaster from happening.

IoT Remote Monitoring Use Cases

IoT remote monitoring solutions can monitor various parameters of equipment and machines, such as temperature, humidity levels, air quality, pressure, and vibration. As a result, companies can ensure their assets are in good health, extending asset longevity and improving safety. In this section, I will walk you through the four key use cases of remote monitoring in the IoT.

Environmental Condition Monitoring

Remote monitoring systems allow companies to measure environmental conditions within warehouses, manufacturing plants, retail facilities, oil & gas sites, and other commercial or industrial environments. The reduced costs of retrofit sensors have been a big reason why environmental monitoring applications have expanded. Refrigeration monitoring, gas detection, and environmental quality control (water, pollution, air quality, etc.) are three of the most prominent use cases for remotely monitoring industrial operations.

Machine Monitoring

IoT sensors, gateways, and loggers are often used to remotely monitor a machine’s health and condition. Manufacturers and energy suppliers are the top users of remote machine monitoring, supporting predictive maintenance use cases. The two main benefits of remotely monitoring machines are visibility and control. Industrial companies spend a lot of money on high-value assets, making it imperative that these assets remain in good condition for a long time and generate maximum Return on Investment (ROI).

Vibration is one of the most common parameters measured with IoT remote machine monitoring. Monitoring vibration levels, often in tandem with the electrical signature or acoustic monitoring, enables enterprises to detect mechanical faults within moving equipment.

While industrial firms are the top users of remote machine monitoring solutions, ABI Research has also observed the growing adoption among commercial users. IoT machine monitoring is vital for companies aiming to minimize energy consumption or ensure the safe operation of elevators/escalators.

Process Monitoring

Another key use case for IoT remote management platforms is process instrumentation, which supports three important outcomes:

- Automated remote data collection

- Automatic shutdown mechanisms

- Granular control mechanisms

Process instrumentation facilitates the measurement of flow and pressure for critical processes. My team and I have seen a growing investment trend in software that supports remote monitoring vendors in improving their use of facility-wide data. Better data use will allow IoT vendors to unlock new use cases for existing industrial markets like tank monitoring.

Structural Health Monitoring

IoT remote tracking can also gauge the structural health of bridges, dams, construction sites, mines, railways, and other civil infrastructure. As pointed out in an earlier blog post, detecting early warning signs of structural damage is nearly impossible. In most cases, corrosion, soil degradation, fatigue, and other detrimental factors cannot be seen by the naked eye. As bridges and other infrastructure continue to age and climate disasters remain on the rise, IoT remote management of these structures is essential for societal safety.

Civil engineers and other infrastructure managers have a wide range of IoT sensors they can leverage, including but not limited to:

- Piezometer sensors (pore/water pressure in the soil of a rock)

- Inclinometer/tilt meters (inclination or tilt of wind turbines, dams, etc.

- Strain gauges (structural strain)

- Accelerometers (gravitational forces and vibration)

- Acoustic emission sensors (high-frequency ultrasonic waves)

- Temperature (of structural materials and surrounding environment)

IoT Remote Monitoring Platforms

This next section lists some of the key vendors offering solutions for remote IoT management. The vendor landscape comprises equipment vendors like Baker Hughes and Danfoss, instrumentation vendors like Banner Engineering and Fortive, wireless IoT specialists like Samotics, and networking vendors like Advantech.

Baker Hughes

Baker Hughes comes from an equipment background. The Houston, Texas-based company sells IoT sensors and measurement equipment alongside additional Original Equipment Manufacturer (OEM) parts and equipment for various industries. Baker Hughes, like other OEMs, targets a range of use cases, particularly the following:

- Process monitoring (e.g., tanks, gauges)

- Machine health tracking (all types of machines for predictive maintenance

- Energy use

- Overall Equipment Effectiveness (OEE))

- Environmental tracking (e.g., gas detection)

Bently Nevada, part of Baker Hughes, acquired Divigraph in 2022, enabling it to grow its capabilities in hardware design and manufacturing. The acquisition allows the company to tighten the integration between the IoT hardware and its existing software and systems.

Danfoss

Industrial automation vendors such as Danfoss, Emerson, and Johnson Controls offer sensors and connectivity within their equipment. In 2017, Danfoss acquired Prosa, a software analytics company, to create its digital services for the food industry. Its telematics unit in refrigeration systems sends data to the cloud, allowing for real time data collection and remote control of units, including refrigeration temperature, machine faults, and energy consumption. Danfoss' IoT solution, ProsaLink, sends telematics data and critical alerts to a mobile app, ensuring that products like medicines and perishable food products in the cold chain remain unspoiled.

Danfoss is enhancing its cloud services to offer customers remote visibility and control of distributed assets. Utilizing embedded IoT sensors and connectivity in its equipment, it has developed various cloud services to manage and act on these data. These include Leanheat for energy systems, AISense for food industries and Heating, Ventilation, and Air Conditioning (HVAC), and DrivePro for remote Alternating Current (AC) drive monitoring.

Banner Engineering

Automation vendor Banner Engineering provides sensors, measurement tools, and industrial Light-Emitting Diode (LED) signage solutions for various IoT markets, along with gateways and controllers. In 2007, it introduced the SureCross WSN solution, a proprietary wireless protocol that connects Input/Output (I/O) sensors to nodes for wireless communication with gateways.

Banner Engineering continues to focus on wireless I/O solutions, launching the Snap Signal solution in 2022/2023. Snap Digital converts various industrial protocols into a common format and supports modular architectures. Banner Engineering has also introduced fully wireless sensors for remote machine and tank monitoring. The company launched the Cloud Data Services platform in 2018 for central data storage, analytics, dashboarding, and alerting. This solution reinforces Banner Eningeering's strategy to become a comprehensive edge-to-cloud solution provider with a strong emphasis on wireless technology.

Fluke (Fortive)

Fortive Corp. is a conglomerate with various brands serving different industries. One key subsidiary is Fluke, which focuses on test and measurement equipment for OT environments. Under the Fluke Reliability brand, Fluke offers IoT remote condition monitoring solutions for maintenance teams, combining hardware and software from PRUFTECHNIK (instrumentation), eMaint (Computerized Maintenance Management System (CMMS)), and Fluke Connect (cloud software).

The eMaint CMMS includes Connect2Assets, which integrates data from control systems and software without additional instrumentation. Fluke Accelix further allows data sharing with third-party systems. Fluke’s tools enable remote asset tracking through wireless vibration sensors and handheld devices, data aggregation and analysis, and maintenance work order creation. In 2023, Fluke acquired Azima DLI for Artificial Intelligence (AI) vibration analytics and had previously invested in Everactive for battery-free sensors.

Fortive also owns several other monitoring companies:

- Comark: Acquired in 2006 for environmental monitoring sensors in the food and healthcare industries, offering wireless devices, thermometers, cloud software, and services for temperature and humidity monitoring.

- Industrial Scientific: Acquired in 2017 for gas detection, combining sensors, gateways, and software.

- Qualitrol: Acquired in 2016 for comprehensive power grid monitoring solutions.

Samotics

Samotics specializes in wireless IoT condition monitoring, assessing the health and energy efficiency of motorized equipment by analyzing current and voltage inside motor control cabinets. It provides both devices and a platform for applications and analytics.

While major instrumentation and automation vendors like ABB and Schneider Electric have in-house Condition-Based Monitoring (CBM) solutions, integrating Samotics enhances the quality of their analytics and flexibility in addressing niche requirements. This integration strengthens Samotics' remote IoT monitoring portfolio, broadening its use case expertise for customers.

Advantech

Advantech is a comprehensive IoT provider, offering a wide range of products. These products include modules, antennas, gateways, control systems, sensors, design services, and cloud services. The company has developed middleware platforms such as iFactory, iHealthcare, and iLogistics to cater to various markets.

Advantech also offers proprietary devices like I/O bridge devices for connecting wired sensors to wireless systems and the WISE 2000 series for remotely tracking parameters such as vibration and electrical current. In 2022, Advantech partnered with Actility to launch an end-to-end solution for rotating equipment monitoring. The solution combines its vibration sensor with gateways, Actility's network server, and its software and analytics. Advantech's strategy provides flexibility to customers, allowing them to build customized IoT monitoring solutions or deploy turnkey solutions with minimal complexity.

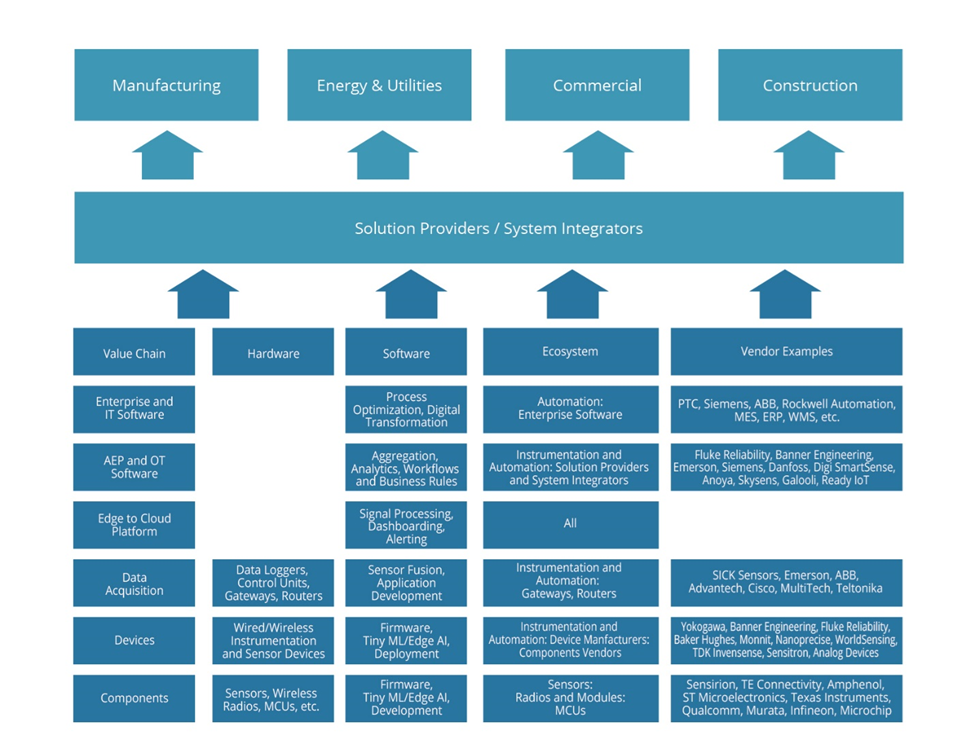

Figure 1: IoT Remote Monitoring Solutions Ecosystem

(Source: ABI Research)

The Future of IoT Remote Monitoring

The IoT remote monitoring ecosystem is steadily expanding, with a diverse vendor landscape providing value for machine builders and end customers. Hardware and software vendors aim to support instrumentation and automation capabilities, while wireless IoT specialists focus on data transmission from edge IoT devices to cloud platforms. ABI Research has observed remote IoT tracking solutions evolving in three key ways as vendors build for future use cases:

- New Remote Device Designs and Features: To support a wider range of industrial IoT use cases, remote monitoring devices are changing in form factor and capabilities. Increased on-device connectivity and the use of retrofit sensors are two notable examples of how monitoring device suppliers are innovating their products. These innovations are critical for monitoring any range of parameters.

- Major Focus on Software Tools: Software investment has been a huge trend in remote monitoring as vendors aim to differentiate their offerings. Some IoT monitoring vendors focus on AI/Machine Learning (ML) models at the edge, while others help customers improve data signal quality. There is also a middle ground, where companies have a more balanced approach to software development.

- Shifting Business Models: Technology vendors are increasingly changing their business models to maximize recurring revenue from IoT remote monitoring solutions. This has been evidenced by numerous acquisitions to expand monitoring capabilities, shifting go-to-market channels, and new pricing models. As IoT devices, software, and business models advance, new opportunities and use cases are emerging in historically underserved markets (e.g., commercial, retail, etc.).

There are three main vendor groups within the IoT remote monitoring market: component vendors, instrumentation and automation suppliers, and wireless IoT specialists. ABI Research recently published an in-depth report detailing the positioning strategies of these various vendors, including:

- Investments being made

- Target markets and applications of remote management (with market forecasts)

- Value chain positioning

Download our Remote Monitoring Markets for IoT: Ecosystem and Market Dynamics Analysis research report today.